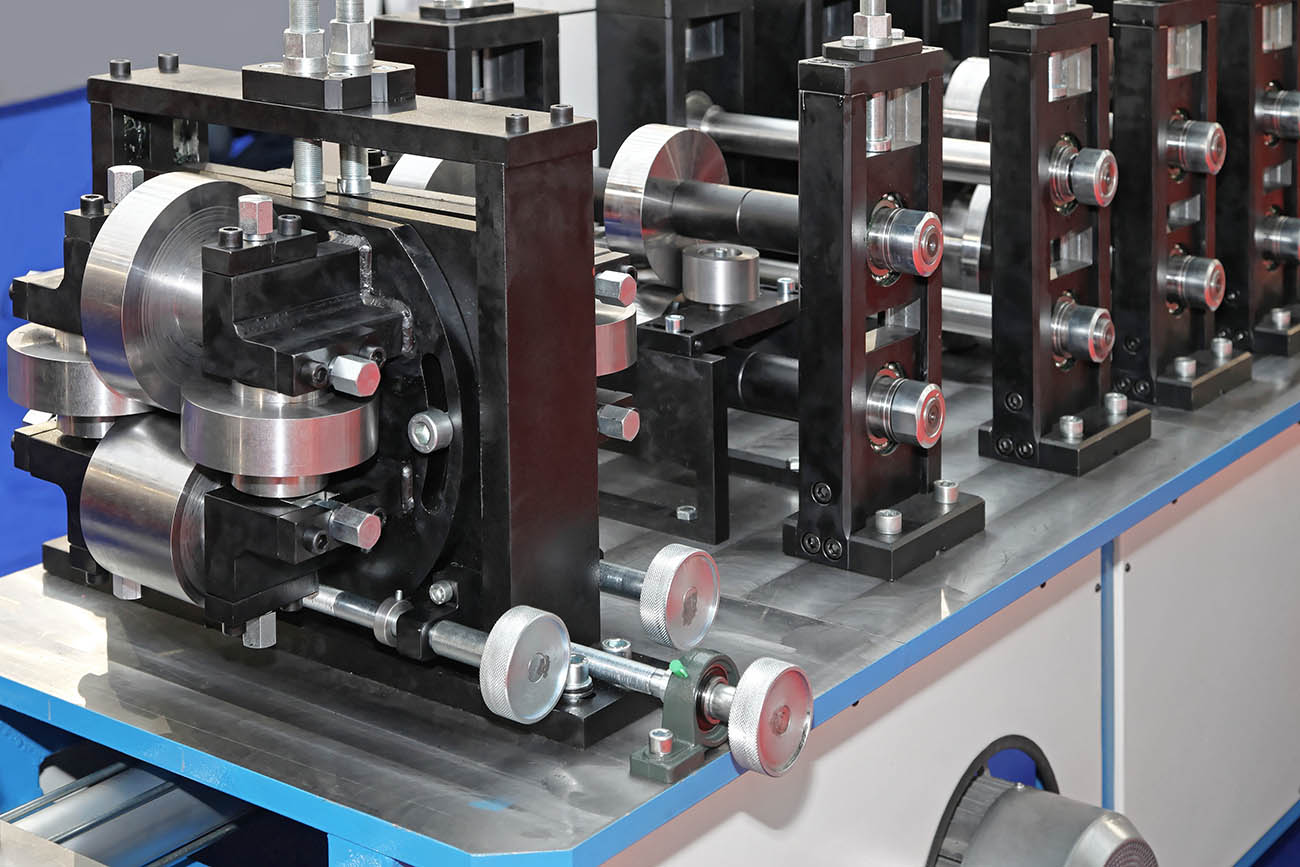

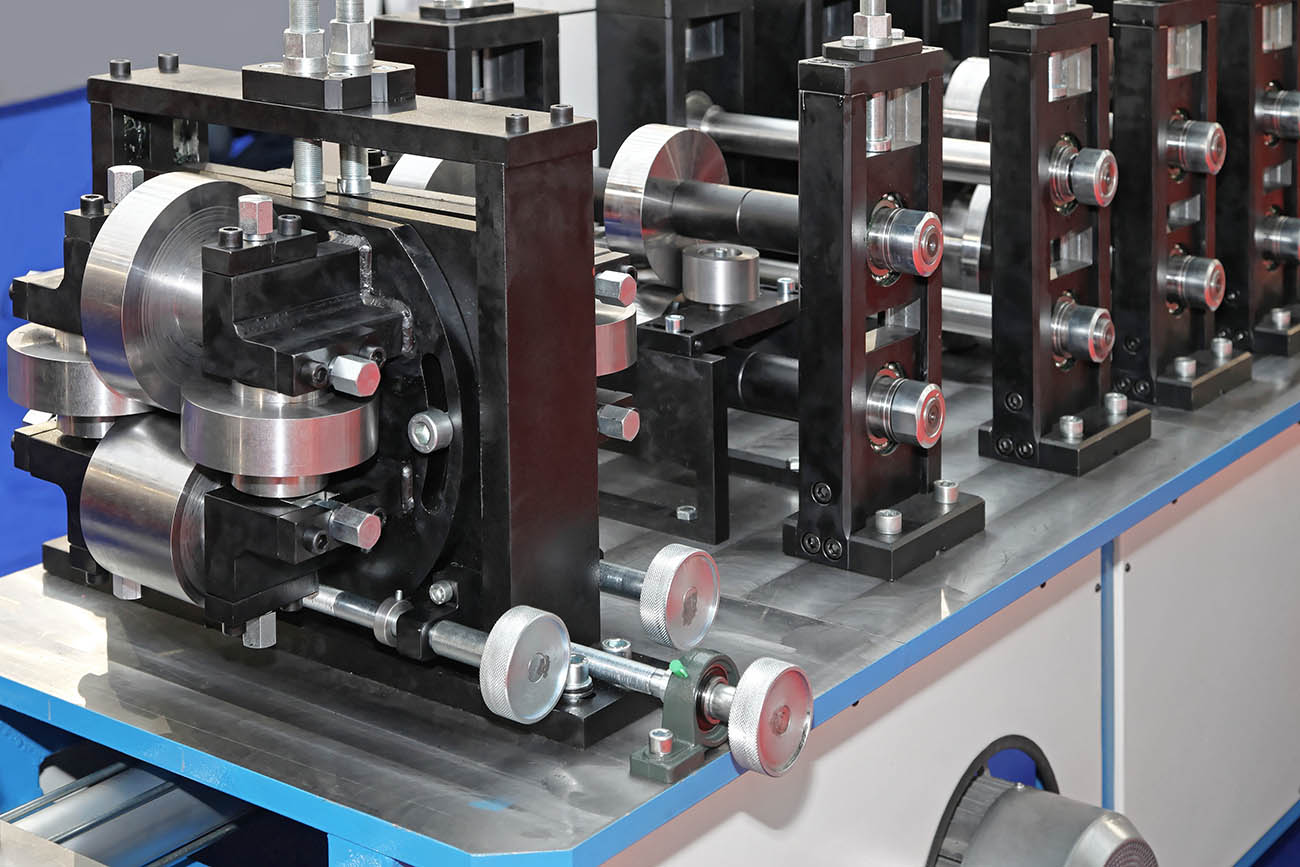

Applicators for external lubrication are delivered in a modular system enabling a system matching the customer application. One or more precision pumps supplies an adjustable quantity of lubricant to the nozzle. On applicators with more than one pump, each pump can be controlled individually. Through a concentric outer tube, pressed-air is lead towards the end of the capillary tube so that the lubricant is atomized and applied to the cutting edge. A long lasting thin film of lubricant reduces the heat-generation in the tool and the specimen.

High speeds are responsible for short tool life, not feed rates. The economic way of increasing productivity is with higher feed rates and lower speed; this is not possible while using traditional coolants. Using ECOLUBRIC® systems, the customer achieves longer lifecycle of tools and shorter production time cycle.